In this blog, 1. Discover the harshness of Indian conditions. 2. How Zana endured to deliver world-class products

Zana Engineered for India’s Harshest Roads. Trusted Across the World

In this blog, 1. Discover the harshness of Indian conditions. 2. How Zana endured to deliver world-class products

How Zana became so tough.

India is not easy to ride in. 35 states. Weather from -50 to +50. Rain-soaked wetlands to harsh deserts. Salt saturated coastlines to tall mountains.

How on God’s Earth do you create anything to survive these specs?

Built for India means it has survived the lush highways to moon-cratered roads, rust-laced monsoons to pure snow. The elements don’t just wear down man and machine. They expose the weak links. Only those forged from fire can dream to survive.

Zana was never born to compete with India and its elements. Zana was born to outlast whatever was thrown at it. Zana was built in awe of the mighty Indian conditions

Zana. Forged from fire. More than metal.

“Road to No Road to What a Highway!

India gives unpredictable a new name. India throws challenges that only the very resilient and stubborn can withstand. Jaisalmer has carpet-like runways for roads. Other parts of India have tough roads. Beaten and bruised tarmac by trucks and the elements. Imagine a motorcycle on it. There are places in India where there is simply no road or unmarked speed breakers and unmapped potholes. The motorcycle and its rider must outlast it all if he wants to ride the next day. It's easy to break levers, bend a chassis, scrape your knees, or simply rejoice on perfect highways.

Indian conditions test you.

It's always a test of mettle and metal Zana is one such story.

Vibhas in 2017 took his bike with a first-gen crash guard and deliberately drop-tested and crashed his bike. That was his version of AutoCAD—real-world testing. He needed to know which products he had to make and what their breaking points were.

Ride it till you break it. Then build. Break. Build. Repeat.

What finally does not break becomes ZANA

Materials that withstand gruesome punishment

Mild steel was a visionary choice. It has flex, and when compounded with alloys, it absorbs energy instead of transferring it to the frame or chassis. When we re-engineered our crash guards with insights from the brutal testing, we made it into kinetic armour which would get us global acclaim.

All bolts are custom bolts. Spec Grade 8.8 or higher hex-torx profiles. The full list of materials is secret, but our products have survived from the Arctic to the Antarctic. Ladakh to the Alps. You are not only doing it right, but it also makes us immensely proud. Today we export to over 20 countries.

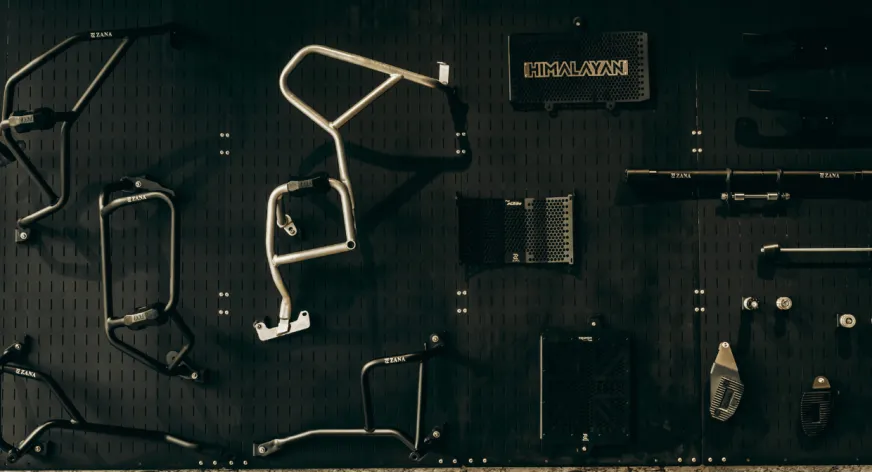

Delivering to the Vision - Full Motorcycle Protection, Luggage, Lighting and accessory systems

It is in our DNA to promote motorcycling, which means just protection alone was never going to be enough. We needed to make luggage, lighting, and riding accessory systems. We did. Today, We are perhaps the only Indian brand with the full spectrum of products. Here are the top products we make

Top Racks

Imported racks were overpriced, at times old stock, or didn’t fit right. We used 2mm thick CRCA steel, laser cut and precision bent to match each bike’s subframe— no drilling, no hacks. Finished with textured powder coating to resist Indian rain and red dust. Carried 25kg (recommended load is 5-7 kg) across potholes, black ice, and complete off-road sections without bending or rusting. Top racks enhance the bike's load ability to no end. Mount a top box and tail bag, and u have more options as a rider.

Aux Lights

Our Gold Series sold out on day one. Not rebranded knock off’s—these are fabricated units that are IP65-rated, dual-colour (white/yellow) LEDs with thermal control and integrated CAN-safe harnesses. Custom clamps for mounting in various places. Built for unpredictable Indian conditions—brightness tuned for highway and mountain fog. Indian riders wanted versatility, reliability and clarity—

We built it in. From 10,000 to 41,000 to suit all riding styles.

Saddle Stays & Pannier Mounts

Every Zana mount is TIG welded from 16-gauge mild steel—not for rigidity, but controlled flex to absorb shock and protect the subframe. Brackets follow OE geometry, no random fitment. Mounts have survived Spiti falls and Goa monsoons.

Our jig-locked manufacturing ensures symmetry—left to right, batch to batch. Saddle stays have a cross brace or X brace to give support unheard of.

Soft & Hard Luggage

Top boxes and Hard panniers use 2.5mm aluminium with polymer corners, antivibration mounts, and steel locking plates. Soft luggage uses 900D fabric with TPU lamination, EVA-reinforced sides, and a heat-resistant base. Indian roads cook bags from the bottom up—we insulated them. Riders helped us iterate every detail—zips, stitching, anchor points.

Bash Plates & Sump Guards

Built from toughened steel, 4mm thick—because Indian off-road hits are blunt force trauma, not light taps. Our bash plates don’t just cover the belly—they extend to the crankcase sides where damage usually starts. Rubber isolation mounts absorb direct hits and stop frame resonance. Sump guards are designed to clear speed breakers even when loaded. Radiator guards? CNC-slotted for airflow, not an afterthought mesh. Every part field-tested on rocky climbs, water crossings, and loaded descents.

Headlight Grills—Designed to deflect stones, bugs, and debris on broken highways and village roads without blocking beam spread.

Master Cylinder Covers—Made from CNC-machined aluminium to prevent fluid cap tampering and damage in tight city parking.

Handlebars—Wider, stronger, and better damped than OEM; designed to reduce fatigue on long rides and survive real-world Indian crashes.

Number Plate Brackets—Built with thicker gauge metal to survive pothole shocks, off-road rattling, and casual two-wheeler nudges.

Phone Holders—Vibration-damped, securely clamped, with surge-protected chargers— engineered after local mounts fried phones and batteries.

Sliders—Milled from Delrin or aluminium with reinforced mounts to absorb low-speed drops common in Indian traffic.

Pucks—Wide-footed and textured to grip gravel, mud, and uneven roadside parking spots— tested across monsoons.

Side Stand Extenders—Enlarged base plates to stop bikes from sinking into hot tar, sand, or slush in Indian conditions.

Paddock Stands—Wider stance and reinforced welds to lift loaded bikes on uneven concrete or cracked garage floors.

Bobbins—Hardened steel pins made for Indian-spec swingarms and wider frame tolerances— no loose fit.

Handlebar Risers—CNC-cut to lift ergonomics for taller Indian riders on commuter or touring posture bikes.

Bolts & Nuts—All critical hardware upgraded to stainless or zinc-coated high-torque fasteners—built to endure Indian weather cycles

Indian condition specs are the ultimate proving ground.

We didn't build Zana for chest-thumping. Zana is our contribution to the India success story. We knew Indian conditions were perhaps the most challenging in the world. We were actually fed up of cheap knockoffs or overpriced imports. We disrupted the market armed with only self-belief and resilience

Zana.

Built in India. Ridden Globally

Forged From Fire. More than Metal